Description

P 1238 – Local material influence on presshardened steel to improve joinability of 22MnB5 parts

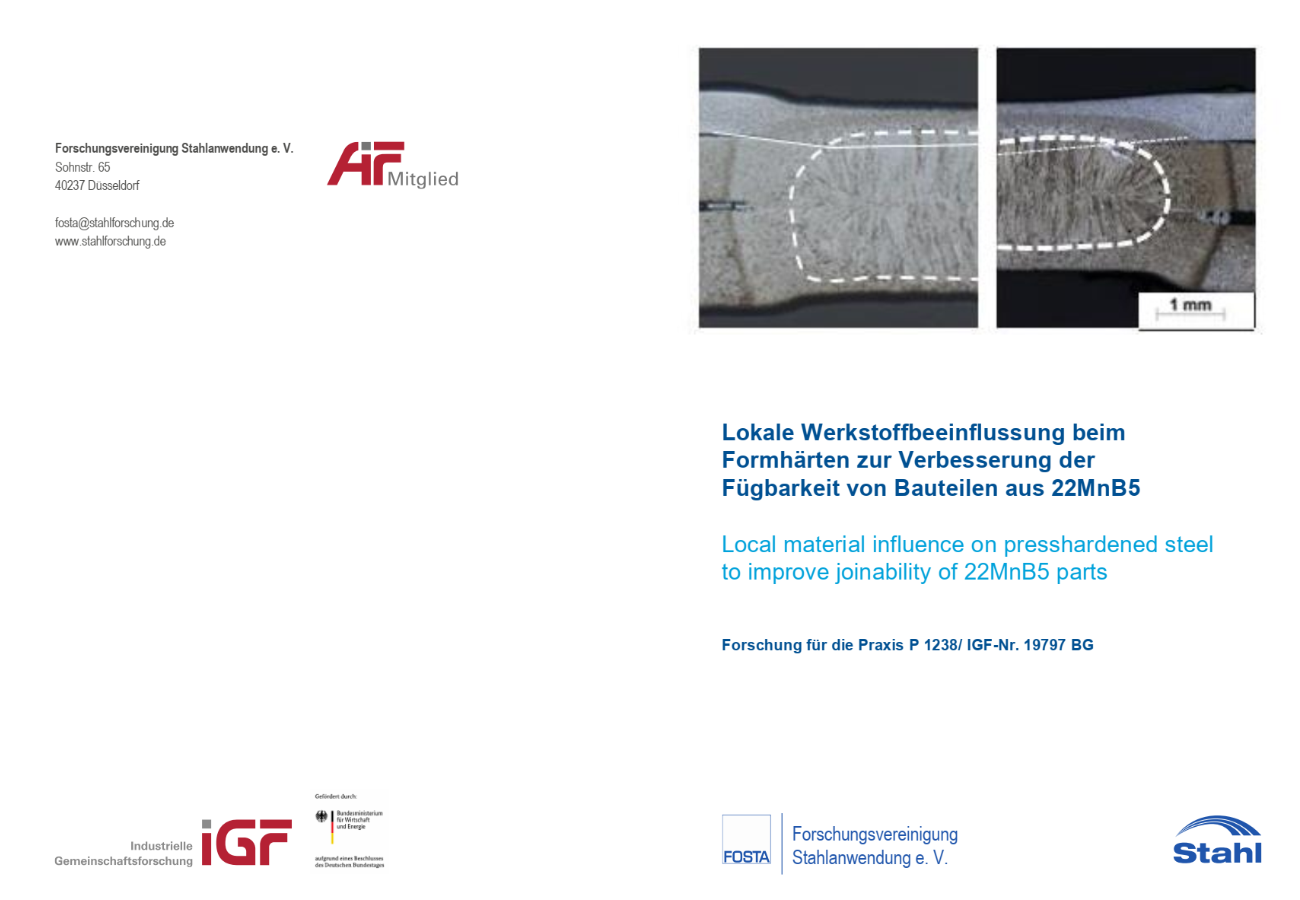

The aim of the research project was to extend the joinability of hot-stamped components made of 22MnB5 by the targeted application of a local thinning. In addition to the local reduction of the material thickness, the material properties were influenced in this area by the formation of deformation-induced-ferrite (DIF). For this purpose, the IFUM Hannover carried out investigations on the hot-stamping of locally deformed blanks. The focus of the IMF Magdeburg was on the extension of the joinability of material combinations with 22MnB5 by resistance spot welding as well as self-pierce riveting.

At the beginning of the project, extensive tests were carried out on a forming dilatometer to determine the process window of DIF formation. The results of the dilatometer investigations were then validated by experimental thinning tests. For this purpose, experiments were carried out on a hydraulic double-column press of the Dunkes company, in which embossing was applied to the blanks by means of a deformation plate in a conventional hot-stamping process. The tests showed, that the conventional hot-stamping process is not suitable to obtain sufficient embossing areas in the sheet material together with the generation of DIF due to the long contact time during the forming an quenching process. Due to the fast punch movement, very short contact times were possible. With the help of the tests on the screw press the generation of DIF could be investigated in a forming process. Since it was not possible to transfer the DIF formation into a conventional hot-stamping process, the potential was finally examined in a numerical simulation.

Published in:

May 2021

Authors:

Prof. Dr.-Ing. B.-A. Behrens, Prof. Dr.-Ing. S. Jüttner