Description

P 1054 – Joining of high-strength steel grades in lightweight structures by means of self-piercing resistance element welding on conventional resistance spot welding machines

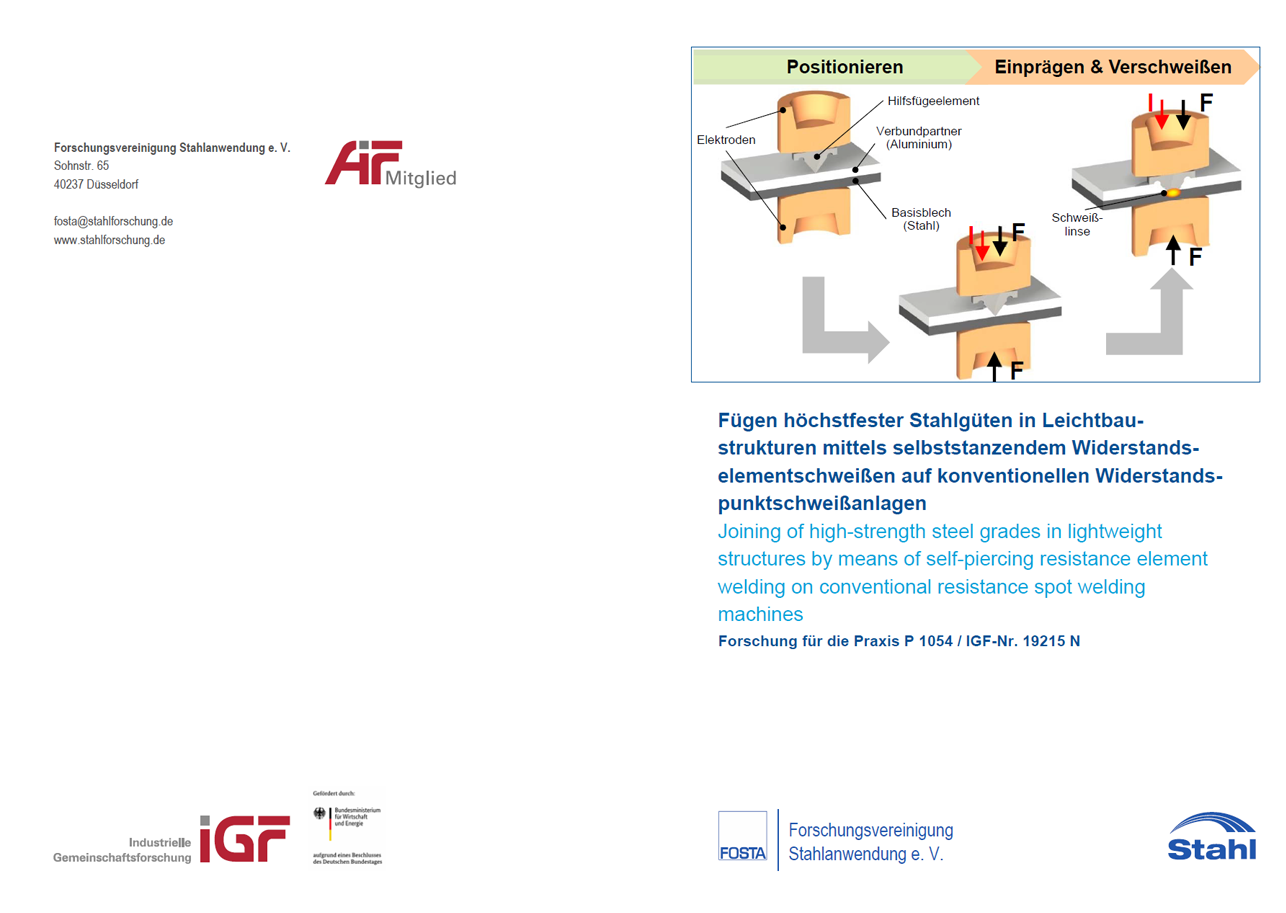

The object of this research project is the development of a novel resistance element welding (REW) process for joining high-strength steels in combination with aluminum alloys. Compared to the current state of the art, a single-stage process and thus the use of conventional resistance welding technology are planned for both the insertion and the welding of the joining partners. The implementation of the results obtained will make an important contribution to the further development of resistance element welding and the economical manufacture of future steel-intensive lightweight structures in mixed construction.

The SME user group includes in particular system manufacturers of element and feed technology, suppliers of connecting elements and suppliers from resistance welding technology as well as automation technology. Due to the high probability of a short-term integration of the process into existing manufacturing processes due to low investment costs, numerous new business and application fields will be opened up for these SMEs. All in all, this creates a direct benefit for SMEs by offering flexible and innovative joining solutions, which helps their customers to realize cost-efficiently manufacture composite structures.

In this research project, process fundamentals were developed which characterise the mechanical and technological properties of single-stage REW joints and the joining process.

The development of rivet geometries that can be punched in, produced by stamping and at the same time suitable for welding and the definition of process parameters for optimum joint formation are milestones to be mentioned here. A further milestone marks the derivation of application guidelines as well as design and manufacturing instructions through a preceding parameter influence analysis for the determination of systematic influencing and disturbing variables on the joining process.

The achieved research results contribute to the process extension of the resistance welding technology and show a possibility with which the joining technology production of steelintensive sheet metal structures in combination with thin aluminium sheets and adhesives is possible. The production of the assemblies can be carried out economically, in line with cycle times and with relatively low investment costs. The efficiency of the resistance welding technology combined with the outstanding properties of high-strength and ultra-highstrength steels allows the production of weight-optimized and rigid passenger cells in mass production, as both the choice of materials and the joining technology are economically advantageous. The advancing development of ultra-high-strength high-performance steels (3rd generation steels) and the increasing trend towards mixed constructions make the need for cost-efficient joining solutions clear. The single-stage REW is a process variant of the REW that can solve the joining task partially.

Published in:

November 2020

Authors:

Prof. Dr.-Ing. G. Meschut, M. Sc. H. Günter