Description

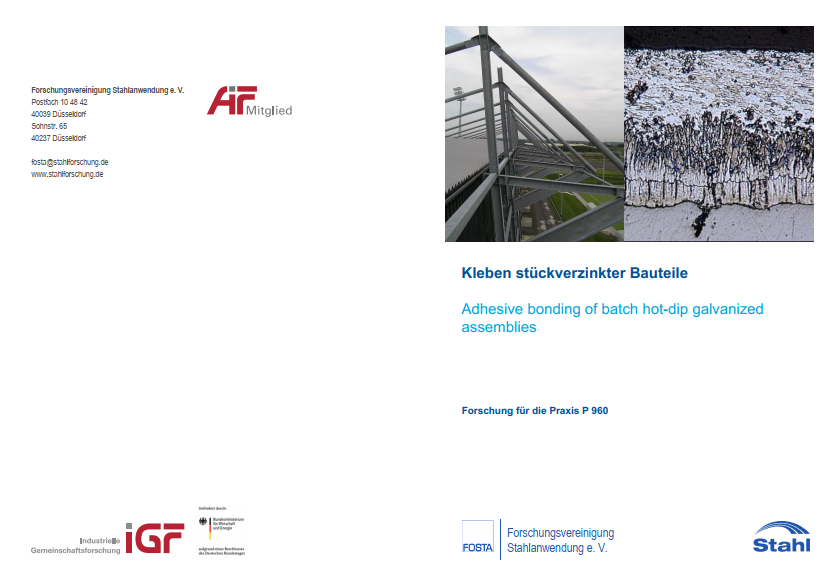

The main objective of this research project was to develop a concept for reliably bonding batch hot-dip galvanized semi-finished assemblies with structural adhesives for commercial vehicles and the building and construction industry. The focus was in particular the

determination of the load bearing capacity of the zinc coating as well as the identification of suitable surface pre-treatment methods.

Based on preliminary tests, the influence of steel alloy and galvanizing method on the adhesion of batch-galvanized surfaces could be investigated. Three high strength and high modulus adhesives were chosen that meet the specific needs of the construction and commercial vehicle industry. Taking into account the steel alloy and galvanizing method, different adhesive surface pre-treatments were tested and classified individually with regard to their erosive impact on galvanized surfaces. Based on a simplified cost-benefit analysis, predominantly wet-chemical surface pre-treatments were selected and applied. In doing so, a layer-selective removal in the pure zinc phase of the zinc coating could be adjusted, using light microscopic studies of metallographic sections.

Besides the common “sweep blasting“ process two pickling media were selected for application on batch-galvanized surfaces in a dipping and spraying process. Furthermore the bare zinc coating condition was investigated without pre-treatment before bonding based on freshly coated and pre-weathered zinc layers. Three specimen geometries were batch-galvanized and subjected to accelerated aging and exterior weathering. Here a significant influence of the surface pre-treatment on the aging resistance of the adhesively bonded joints could be observed.

The successfully applied chemical surface pre-treatments were accurately described in a pickling instruction to ensure a reliable processing of batch-galvanized small scale components and to serve as a contribution to an application guideline. The results obtained from standardized test specimens could be transferred to small-scale specimen and the applicability of the pickling instruction was confirmed during the preparation of small-scale specimen. Using component tests, the load transfer in the steel-zinc-adhesive laminate could be investigated in practical component geometries, the applicability of the surface pre-treatments to larger scale assemblies could be confirmed and the numerical calculation models were calibrated and optimized. Finally, construction and design rules for the building practice were derived. The obtained knowledge enables an adhesive joining of batch hot-dip galvanized semi-finished products with high durability.

FOSTA – Research Association for Steel Application

January 2019

Only available in German language.