Steel-Iron Test Sheets (SEP)

The steel-iron test sheets contain guidelines on the proper performance of test procedures to determine certain material properties. The task of the test sheets is to standardise test conditions in advance of standardisation so that the test results are comparable. In this way, they enable or facilitate the agreement of processing and/or performance properties and the exchange of experience on these. During their elaboration, the knowledge and experience of steel manufacturers and steel users as well as, for example, technical inspection organisations are taken into account. With the help of the steel-iron test sheets, experience is to be gathered in the performance of material tests, which will then be used for its standardisation when a test method is generally proven.

All reports exclusively in digital form.

Showing 1–25 of 47 results

-

SEP 1950: Heat Stability Test on shafts

71,03€ -

SEP 1572: Microscopic testing of free-cutting steels for sulfide non-metallic inclusions using standard images

50,47€ -

SEP 1611 – Evaluation of Centerline Segregation of Continuously Cast Slabs

71,03€Note:

For calibration or verification of appropriate evaluation software according to method C, the guideline diagrams listed in Annex A can be obtained in digital form from the Steel Institute VDEh.

Contact Person:

Dr.-Ing. Stefanie Brockmann

Werkstofftechnik

Stahlinstitut VDEh

im Stahl-Zentrum

Sohnstraße 65 | 40237 Düsseldorf -

SEP 1571: Table/Poster for SEP 1571: Evaluation of inclusions in special steels based on their surface areas

24,30€ -

SEP 1571: Evaluation of inclusions in special steels based on their surface areas – Part 3: Method E

29,91€ -

SEP 1571: Evaluation of inclusions in special steels based on their surface areas – Part 2: Methods K and M

29,91€ -

SEP 1571: Evaluation of inclusions in special steels based on their surface areas – Part 1: Basics

85,89€ -

SEP 1571: Evaluation of inclusions in special steels based on their surface areas – Part 1 to 3

111,21€ -

SEP 1928: Non-destructive surface hardness testing on ferromagnetic steel products with electromagnetic methods

41,12€ -

SEP 1231: Determination of Mechanical Properties on Joined Sheet Metals by High-Speed Tensile Testing

75,70€ -

SEP 1850: Cyclic corrosion testing of materials and components in automotive construction

41,12€ -

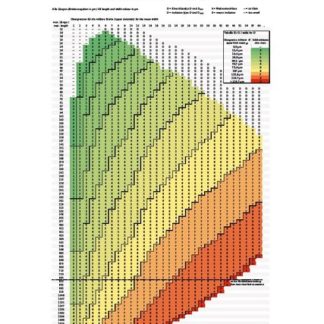

SEP 1664: Supplementary sheet to SEP 1664: Derivation of equations by multiple regression for the calculation of hardenability in the Jominy end quench test on the basis of the chemical composition of steels

151,40€ -

SEP 1235: Determination of the modulus of elasticity on steels by tensile testing at room temperature

59,81€ -

SEP 1245: Material Approval Process for Automotive Sheet Steel (Cold Forming)

59,81€ -

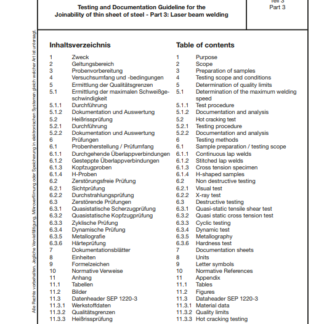

SEP 1220: Testing and Documentation Guideline for the Joinability of thin sheet of steel – Part 3: Laser beam welding

130,84€ -

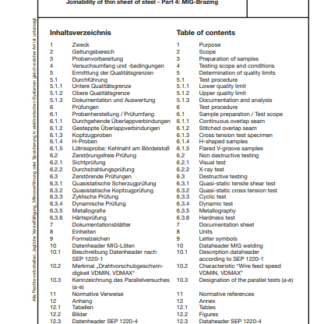

SEP 1220: 11.18 – Testing and Documentation Guideline for the Joinability of thin sheet of steel – Part 4: MIG-Brazing

121,50€ -

SEP 1220: Testing and Documentation Guideline for the Joinability of thin sheet of steel – Part 1 to 4

302,80€ -

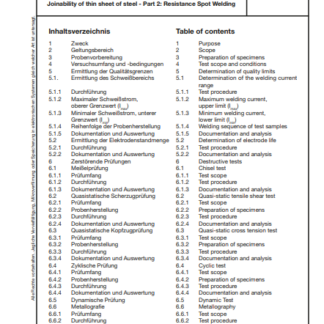

SEP 1220: Testing and Documentation Guideline for the Joinability of thin sheet of steel – Part 2: Resistance Spot Welding

111,21€ -

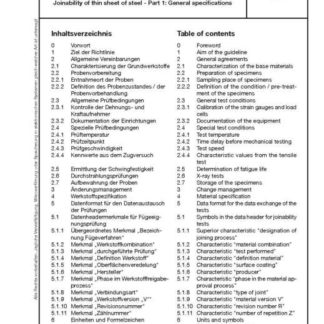

SEP 1220: 11.18 – Testing and Documentation Guideline for the Joinability of thin sheet of steel – Part 1: General specifications

50,47€ -

SEP 1670: Determination of brittle-ductile transition temperature FATT and other characteristic properties

55,14€ -

SEP 1926: Automated ultrasonic inspection of rotation symmetrical steel forgings with computer controlled data acquisition and processing

29,91€This specification deals with the ultrasonic testing of steel forgings, in comparison to SEP 1923 with computer-based data acquisition and processing for the detection of internal flaws by the pulse-echo technique.

The objectives of this specification are:

– to improve the reliability of test data,

– to enhance the reproducibility of results by recording of test data,

– to make all test data convertible into a format independent of equipment for subsequent analysis of the results,

– to provide an improved visualization by the use of appropriate software,

– to reduce acceptance testing. -

SEP 1927: Ultrasonic Immersion Testing Method for Determining the Macroscopic Cleanliness Rate of Rolled or Forged Steel Bars

59,81€ -

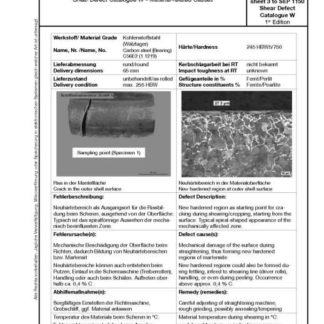

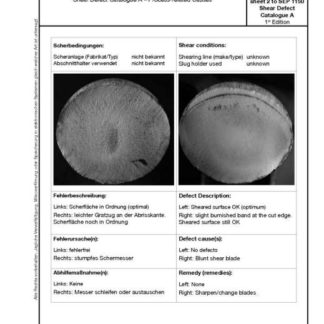

SEP 1150: Cold Shearability of Steel Bars and Rods

34,58€ -

SEP 1150: Supplementary sheet 2 to SEP 1150 Shear Defect Catalogue W 1st Edition

50,47€ -

SEP 1150: Supplementary sheet 2 to SEP 1150 Shear Defect Catalogue A 1st Edition

50,47€

Showing 1–25 of 47 results